Varilla De Tubo De Fibra De Carbono Para Diámetro Sistema De Riel De Varilla De 19 Mm Kit De Jaula De Cámara De Enfoque De Seguimiento Para Cámara Foto De Diámetro Sistema De Riel De Varilla(15cm)

QUARKZMAN 2 Piezas Tubo de Fibra de Carbono 12 x 14 x 170mm Superficie Brillante Barra 3K Enrollada en Rollo de Fibra de Carbono Pura para Aviones RC Multicóptero

Tija de sillín de fibra de carbono, ligera, poste de tubo de asiento con cabeza recta (3K mate 27,2-350 mm)

DMiotech 2 Paquete 6mmx4mmx200mm Carbono Fibra Ronda Tubos, 3K Rollo Envuelto Brillante Carbono Tubo para RC Cuadricóptero, RC Avión

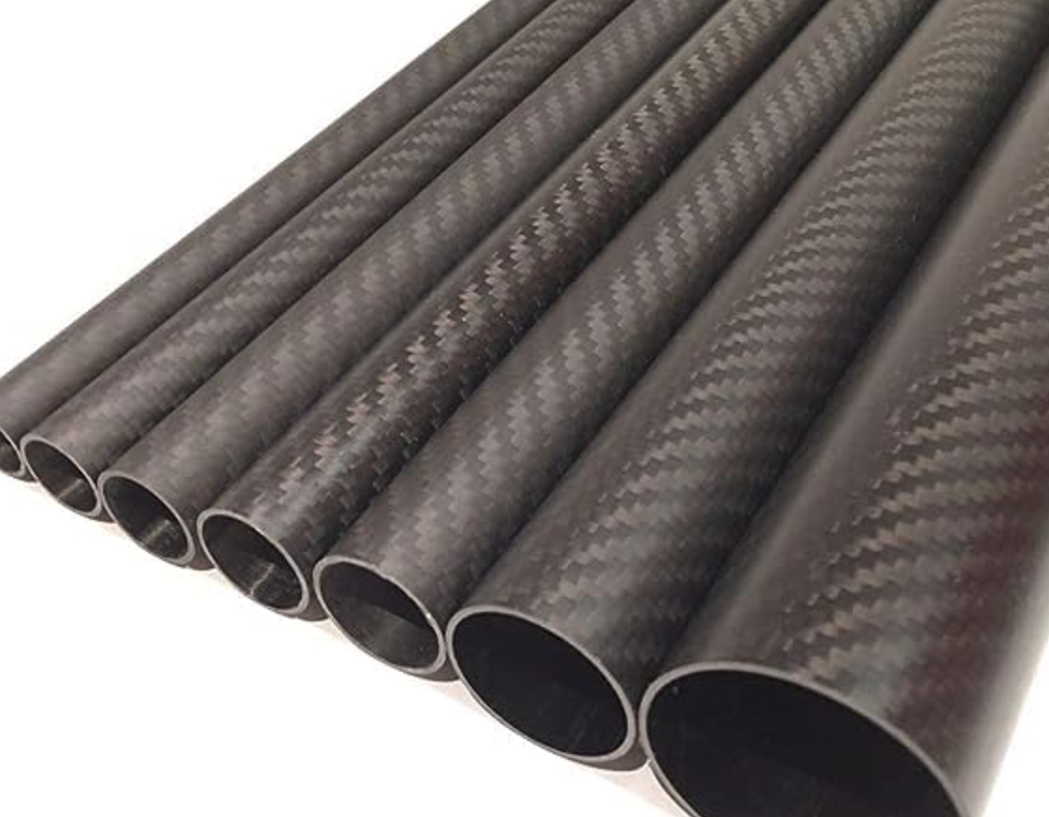

Carbon fiber is a revolutionary material that has transformed multiple industries thanks to its lightweight and strong properties. In this article, we will explore the complete process for manufacturing carbon fiber tubes , which are used in applications ranging from automotive to aerospace.

What is Carbon Fiber?

Carbon fiber is composed of extremely thin filaments that are made of carbon. These filaments are bundled together to form threads that can be woven or wound into various configurations. The main advantage of carbon fiber is its high strength-to-weight ratio, meaning it provides great support without adding extra weight.

Necessary Materials

To get started with making carbon fiber tubes, you will need to gather the following materials:

-

Epoxy Resin: This ingredient acts as a binder for the fibers.

FansArriche Resina Epoxi Transparente No Tóxica 385g/360 ml, 1: 1 Relación de Resina Fundida Cristalina, para Madera, Creaciones Artísticas, Restauración, Azulejos de Pared, Resina epoxi Manualidades

Kit Resina Epoxi Transparente RHINO Smart Solutions - Set de Iniciación Resina Liquida + Endurecedor (1:1) con Accesorios, Pigmentos y Molde para Manualidades, Joyería, Bricolaje, Recubrimiento

-

Carbon Fibers: You can find them in the form of threads, fabrics or mats.

Hojas de Fibra de Carbono, 100% 3K Placa de Fibra de Carbono Mate de Sarga 75mm X 125mm X 0,5mm 1mm 1,5mm 2mm 3mm Espesor, Panel de Fibra de Carbono(2 mm)

Hoja de Fibra de Carbono 75x125x0.5mm Disponible en 0.5mm 1mm 1.5mm 2mm 3mmespesor 100% 3K Hoja de Fibra de Carbono Sarga Mate(75x125x0.5mm/3.0x4.9x0.02inch)

- Molds: To shape the tubes, it is essential to use high quality molds.

QUARKZMAN 25mm x 30mm 3 Pies Transparente Vinilo Tubo x 1uds Plástico Flexible Manguera Tubo para Industrial Agricultural Ingeniería, [PVC]

sourcing map PVC Manguera Tubo, 2mm(0.07") ID x 4mm(0.15") OD 3 M Transparente Vinilo Tubería, Plástico Flexible Agua Tubo

- Gloves and Mask: Safety is paramount, so wear proper protection.

Twinzee Guantes Anticortes de Alta Tecnología (Nivel A9/F) Protección Total y Flexibilidad Máxima - Guantes Anticorte de Acero Inoxidable - Talla M

Oregon Guantes de Motosierra Anticorte, Protección de la Mano Izquierda – Talla L (Talla 10) (91305L)

-

Masking Tape: To protect specific areas in the mold.

Scotch Cinta de Enmascarar Clásica, Beige - 24 mm x 50 m, Paquete de 3 Rollos - Cinta Adhesiva para Pintores, para Pintar y Decorar

GAUDER Cinta de pintor (24 mm x 50 m) | 3x Cinta de carrocero | Cinta para pintar | Cinta de enmascarar

Manufacturing Process

The manufacturing process of carbon fiber tubes can be broken down into several stages, which are described below:

Molding Preparation

First, you need to prepare the mold where the tube will be formed. Apply masking tape around the areas you don't want the material to stick to. This will ensure that the tube can be easily removed once it hardens.

Impregnation of the Fibers

The next step is impregnation of the carbon fibers. This is done by dipping the fibers into the epoxy resin. Make sure that each fiber is well covered and that there are no air bubbles left.

Coating and Molding

Once impregnated, the fibers must be rolled or placed into the mold. This requires patience and precision to ensure even distribution. After placement, it is important to compact the fibers to maximize the strength of the tube.

Cured

The next step is to allow the tube to cure properly. This usually involves leaving the tube in a dry, temperature-controlled location for the resin to harden. Depending on the resin used, this process can take from several hours to days.

Tube Finish

After the tube has cured, it's time to unmold it. Carefully remove the tube from the mold. This part of the process may require a bit of effort, depending on the complexity of the mold and the amount of resin used.

Sanding and Polishing

Once removed from the mold, the tube may need to be sanded or polished. This will help to remove any imperfections and give it a more aesthetically pleasing and functional finish.

Carbon fiber tubes have multiple applications, from home automation components to support elements in aeronautics. They are also widely used in the automotive industry to improve performance and fuel efficiency.

Comentar: